If you need to quickly increase productivity and quality whilst reducing costs, a really effective tool to use is Failure Mode Effects Analysis (FMEA).

Despite the unwieldy name, it is a simple and quick tool that you can apply to your processes which can generate rapid results, it has been successfully used by NASA, Ford, the NHS and countless other private sector organisations.

What’s in the name?

It is an unwieldy name, but if we break it down it begins to make a lot more sense:

Failure Modes — these are ways in which a process can go wrong or cause undesirable outcomes and cost implications

Effects — is the result from the failure mode on quality/ costs

Analysis — systematic approach to failure modes and their effects, to increase quality and reduce costs

Why should you use FMEA?

Firstly, it can help stop bad stuff happening to your processes, when bad stuff happens it increases costs, reduces productivity and impacts customer service.

Secondly, it can help you make rapid improvements to existing processes or to “design out” issues in new processes after all earlier detection of failure means a lower cost to resolve the problem.

FMEA helps you to take a structured approach to identifying and understanding areas of failure, so they can be addressed, reducing the negative impact on outcomes.

How to conduct a FMEA:

10 Step process

Select a process to focus on — this should be a process that is important to the firm this could be because its high volume, it drives significant cost or it has a big impact if it goes wrong — ensure the team agree and understand the scope (the specific process to be analysed)

Form the right team — an FMEA can be created in one day, but to do that you need the right people. The right people often include; front line colleagues involved in the actual process, those who know the service and process (end to end) and those that understand the needs of the customer

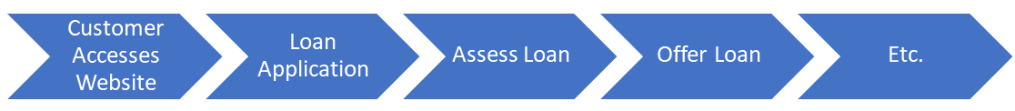

Map out the process — the team should walk through the process end to end at a good level of detail (no less than 5 steps, ideally at least 10). It is important to ensure that everyone agrees the output of this step. If people don’t this might be because the scope is different (existing vs. new customers) or because the process is not consistently followed. If a scope problem — re-frame the scope, if it’s a consistency problem then an FMEA will have limited value until the variability is addressed

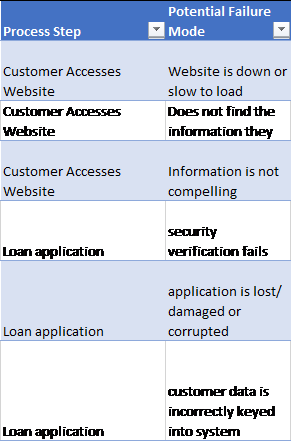

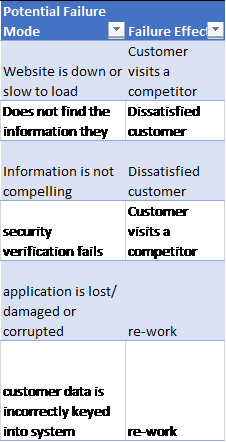

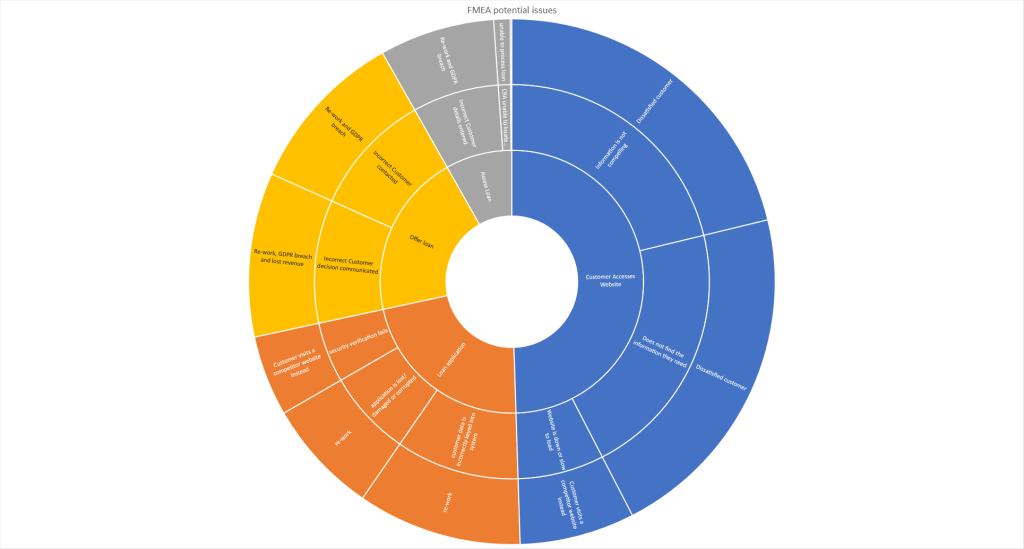

Identify the potential problems — for each process step use existing data (where available) or the experience and knowledge of the team to identify where the process could go wrong (e.g. agent incorrectly diagnoses the problem)

Describe the effect the problem has — for each problem articulate the impact on the customer, business or wider stakeholder

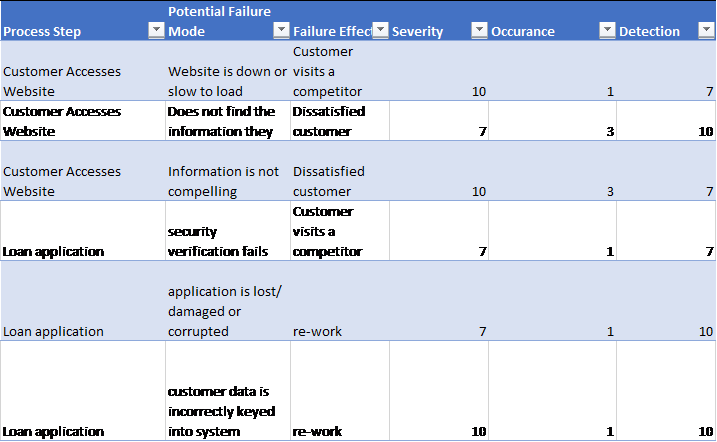

Rate the issue — for each issue rate the Severity of it happening (on a scale of 1–10), the Likelihood of it happening and the chances of it being Detected (before getting to the customer) — for detection the scoring is reversed (10–1, where 1 is very likely to be detected)

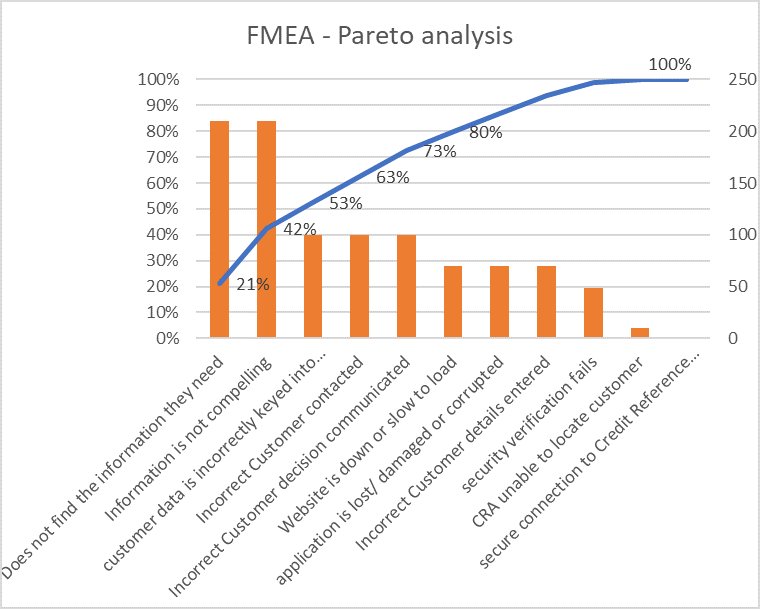

Rank the issues by priority score — calculate the priority (known as the RPN Risk Priority Number), by multiplying Severity x Occurrence x Detection. This will identify the biggest potential issues, you can now use Pareto analysis to focus effort on the areas of biggest impact

!!Warning!! — The assessment of Severity, Occurrence and Detection is likely to have been done using a mixture of available data and opinion. This subjectivity means that the outcomes from the analysis may not be 100% accurate. The aspiration is that it is close enough to ensure you are focusing on the right areas.

Understand the causes — For each ‘priority’ issue you need to develop an understanding of the root cause of the issues

Develop and implement solutions — identify potential solutions for the priority issues that can be applied in the short term and longer term. Take forward identified solutions to reduce the impact of the issues on your business process

Track success — repeat the FMEA following implementation of the solutions, to confirm if the previously identified problems have been addressed but also to identify if other issues are now causing issues

Ultimately, FMEA can an effective way to fairly rapidly systematically identify real or potential issues that a process encounters which have an impact on customer service, process capability, quality and productivity. This then provides the foundation for implementing solutions to increase overall performance.